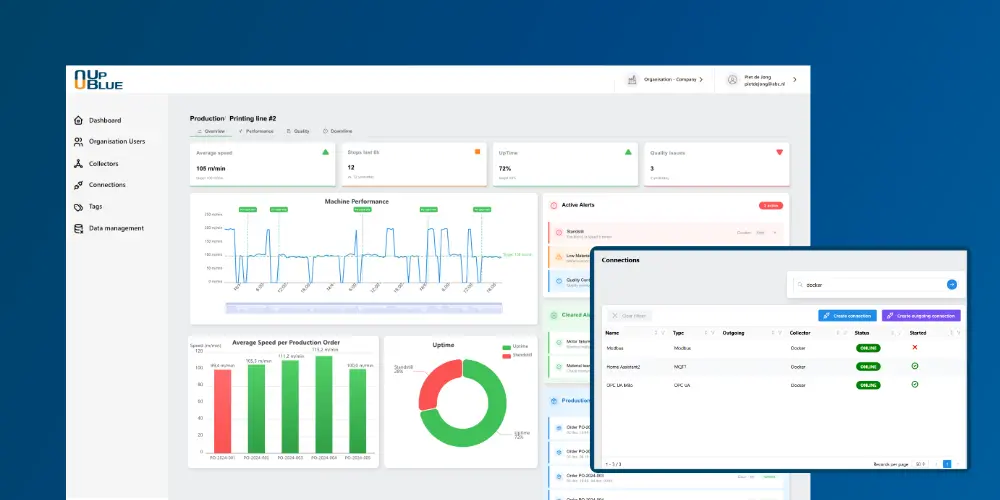

Operation Tracking

Insight per Order or Batch

Monitoring and analysis of production operations. Track start/stop times, analyze batches and optimize processes based on machine data.

Batch Performance

B-2024-003

Quality

99.2%

Efficiency

96.8%

Yield

98.1%

B-2024-005

Quality

96.8%

Efficiency

92.1%

Yield

94.7%

B-2024-002

Quality

97.1%

Efficiency

89.5%

Yield

95.2%

B-2024-001

Quality

98.5%

Efficiency

94.2%

Yield

96.8%

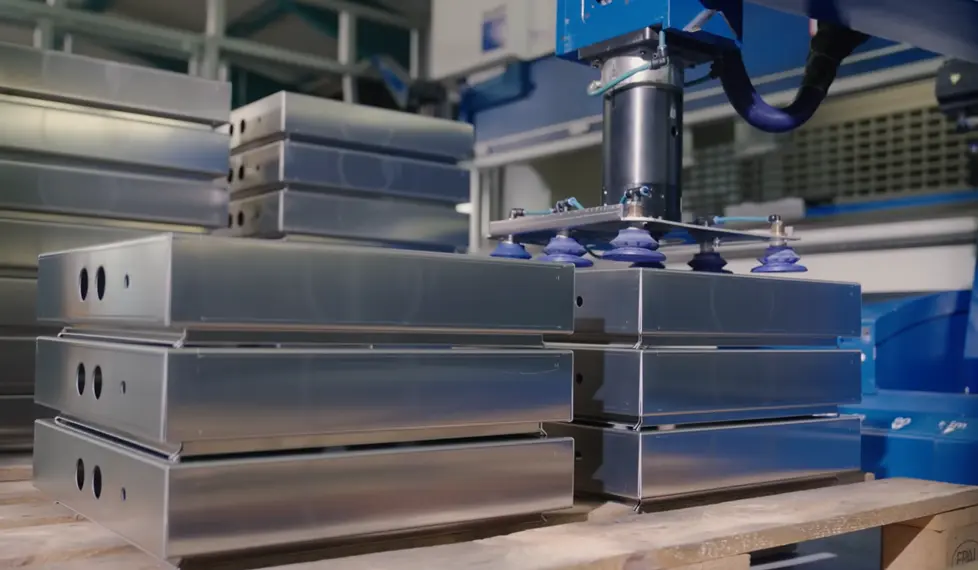

Monitoring & Process Monitoring

Operation Tracking creates the connection between your production orders/batches and machine data. By linking orders to machine parameters, you get complete insight into how each batch is produced.

Order-Machine Coupling

Connect production data with production orders and batches. Machine parameters and machine data are automatically linked to a specific order or batch.Batch-specific Process Monitoring

Monitor critical parameters (temperature, pressure, speed) per batch and order. Track how process data affects the final quality of specific orders.Order-based Comparison

Compare how different orders/batches perform under similar machine settings. Identify which combination of order parameters and machine data yields optimal results.

Live Order & Batch Tracking

Production Line A

Order: PO-24-8891

Max Temp

85.4°C

StDev Pressure

0.8bar

Cycle time

45.2s

Assembly Station 2

Order: PO-24-8892

Vibration

2.1mm/s

Torque

98.5%

Alignment

0.05mm

Packaging Unit

Order: PO-24-8893

Seal Strength

142.8N

Speed

28.5/min

Rejection

0.8%

Operation

Real-time data collection from industrial equipment via Modbus, OPC UA, and MQTT protocols.

Load manually, via Excel or via ERP orders and batches into the system.

Machine data is automatically aggregated per order/batch

Compare production quality between different batches and identify improvement points.

Connect with Power BI for extensive reporting and dashboard creation.

Orders & Batches linked to Machine Data

Operation Tracking forms the bridge between your ERP orders/batches and machine data. Through automatic linking of production orders to machine parameters via UpBlue, you get complete traceability from order to final product.

- Automatic linking of production orders to machine data

- Batch-specific tracking of process parameters and quality data

- Order-based analysis: compare how different orders perform