Increase your productivity with UpBlue's OEE measurement

Improve your production with OEE monitoring. Detailed insight into availability and performance forms the basis for structural process optimization. Minimize downtime, increase output and strengthen your delivery reliability.

Overall Equipment Effectiveness

OEE

0%

Availability

0%

Performance

0%

Quality

0%

Machine Efficiency (%)

OEE Trend (Last 7 Days)

OEE Dashboard

Detailed insight per production line, machine and shift. OEE and availability support targeted improvements.

Continuous Monitoring

Current insight into performance and availability.Trend analysis

Recognize recurring patterns and discover improvement points.Process optimization

Analyze your processes to reduce waste and increase output.

Performance analysis

Long-term insight for structural improvement

OEE Trend Chart

Order & Batch

| Batch ID | Efficiency (%) | Status |

|---|---|---|

B-2024-001 | 94.2% | Approved |

B-2024-002 | 90.5% | Approved |

B-2024-003 | 96.8% | Approved |

B-2024-004 | 78.9% | Rejected |

B-2024-005 | 82.1% | Review |

Deviation monitoring

Targeted detection of process deviations.

Process monitoring

Monitoring of critical machine values.Downtime detection

Automatic detection of production stops and downtime.Deviation notification

Receive warnings for deviations from the norm.

Production analysis

Production line 1

86.4 % (193.4 min)

Production line 2

82.1 % (90.2 min)

Production line 3

78.9 % (88.7 min)

Production line 4

51.2 % (96.1 min)

What is OEE?

OEE (Overall Equipment Effectiveness) measures the effectiveness of your production process by combining availability, performance and quality. It provides a powerful tool to analyze and improve the performance of your machines over time.

×

×

= OEE

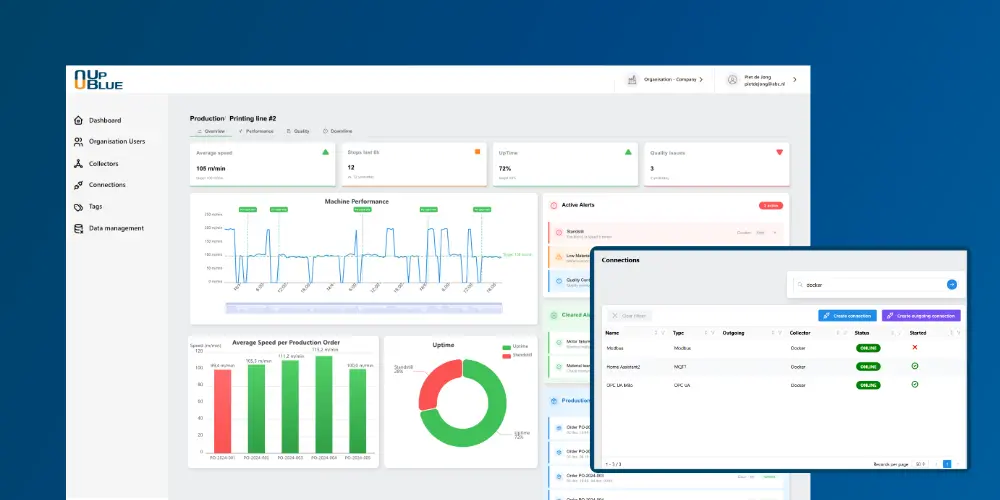

Manage your complete OEE environment in one Platform

The UpBlue platform offers a complete, user-friendly web environment where you connect your machines, build dashboards and configure OEE measurements. From data connections to visual reports - everything is accessible via your browser without complex installations or IT infrastructure.

The Benefits

Smart Integrated

Optimize your Production

Discover how UpBlue improves your production with real-time OEE monitoring and detailed performance analyses. Get insight into availability, performance and quality per production line and machine. Minimize downtime, increase your output and strengthen your delivery reliability with data-driven decisions.