Data-Based Preventive Maintenance

Smart Maintenance

Minimize unplanned downtime and increase the reliability of your machines. Real-time condition monitoring with predictive analyses ensures timely maintenance before failures occur.

Preventive Maintenance

Vibration

0 mm/s

Alarms

0

Health Score

0%

Vibration Measurements (30d)

Alarms (Last 7 Days)

What is Preventive Maintenance?

Preventive maintenance is a proactive maintenance approach where maintenance is performed based on real-time data analysis, rather than reacting after a failure.

Reduce failures and downtime

Increase the productivity of your factory through proactive failure prevention. Unplanned downtime disrupts production and leads to significant cost losses. With UpBlue you transform from reactive to preventive maintenance and prevent failures before they occur.

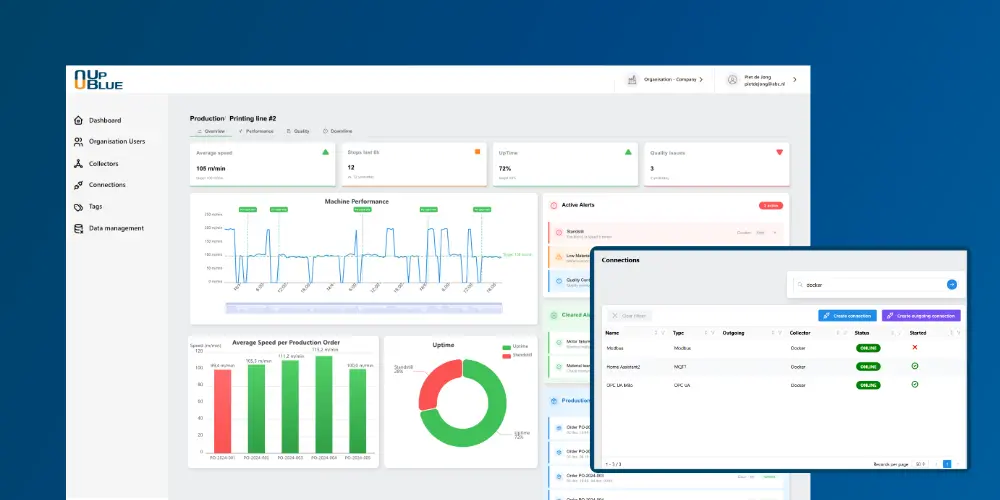

Real-time Condition Monitoring

Continuous insight into the status of your equipment with real-time detection of deviations in temperature, vibrations, operating hours and other critical parameters.

Historical and Predictive Analyses

Data-driven Maintenance Predictions

Use historical data to predict future maintenance moments. Identify patterns and trends to prevent failures before they occur.

Trend analysis

Machine behavior over time

Alerts and Notifications

Receive immediate notifications for deviations. Configurable alerts ensure that the right team is informed at the right time.

Real-time Alerts

Notifications via email, App or dashboard when parameters are outside normal values.Per machine or parameter

Configurable notifications per machine or parameter for targeted alerts.

Integrations and Connectivity

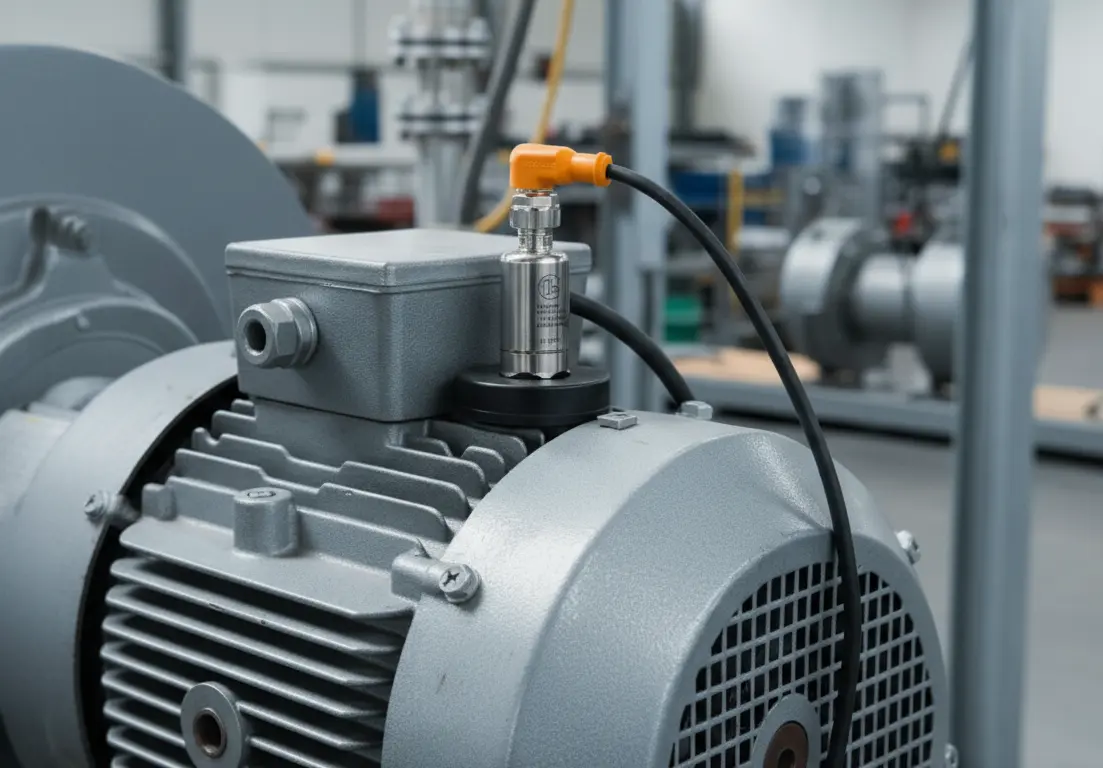

Expand your monitoring with additional sensors via modern industrial standards. Data integration provides a complete picture of your machine status.

IFM IO-Link Sensors

Easily add additional sensors to existing machines.

Machine integration

UpBlue integrates via Modbus, OPC-UA or MQTT with existing machines and systems.

More efficient maintenance teams

Unplanned failures not only disrupt production, but also the work of your Technical Service. Ongoing maintenance projects must be interrupted for acute failure resolution, leading to inefficiency and higher costs.

With UpBlue's preventive approach, your Technical Service plans maintenance at the optimal time. This ensures a structured maintenance process, better resource planning and increased effectiveness of your maintenance team.

Benefits of Condition Monitoring

0%

Less Downtime

Reduced unplanned downtime

0%

Cost Savings

Lower maintenance costs

0%

Longer Lifespan

Postponed replacements

0%

Uptime

Increased availability

Proven results through data-driven preventive maintenance. Reduce costs, increase uptime and optimize your maintenance strategy.

Maintenance Plan

Preventive Maintenance does not start with smart software, but with a solid maintenance plan. Our maintenance specialists help you develop effective maintenance plans and strategies. From analysis to implementation of your preventive maintenance program.