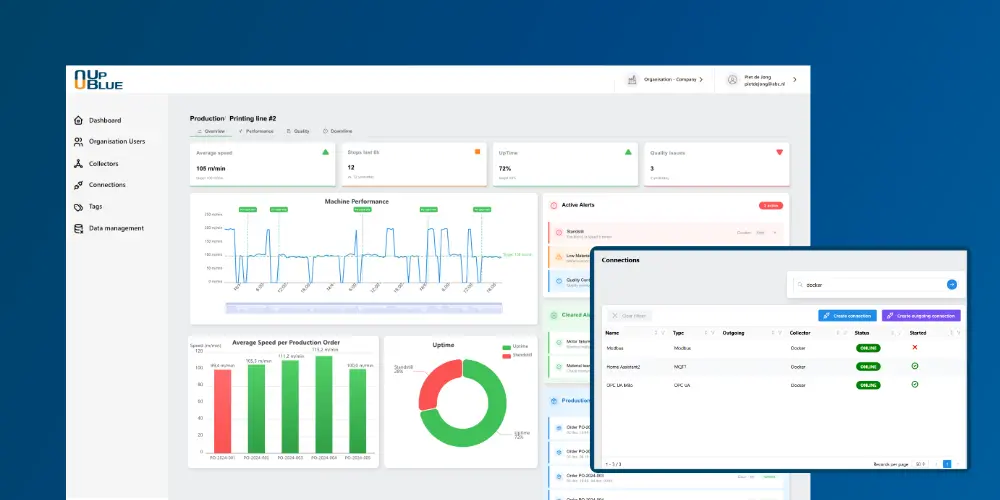

Connect your machines in minutes

Connect any machine, regardless of brand or protocol. From modern PLCs to legacy equipment — UpBlue supports industrial protocols such as Modbus, OPC UA, MQTT and S7.

No programming knowledge required. Configure connections visually via our Management Environment and start collecting production data immediately.

See what's really happening

Real-time dashboards show exact machine status, production figures and OEE values. Historical data helps you recognize trends and predict problems before they occur.

From operator to management — everyone has access to the same current information. Make data-driven decisions based on facts, not assumptions.

Optimize and improve

Identify bottlenecks, reduce downtime and increase your OEE. Set up intelligent alerts that warn you of deviations, so you can intervene immediately.

Share production data automatically with your ERP, MES or other systems. Determine performance per order or batch and continuously improve.

One Platform for Your Entire Factory

By centrally collecting data from machines, operators and ERP systems, UpBlue always provides current, reliable insights. Direct visibility into what is happening and concrete control to improve every step on the shop floor.

Smart solutions for every factory

Discover how UpBlue transforms every aspect of your production operations with our comprehensive industrial IoT platform

Overall Equipment Effectiveness (OEE)

OEE

0%

Availability

0%

Performance

0%

Quality

0%

Machine Efficiency (%)

OEE Trend (Last 7 Days)

Data-Based Preventive Maintenance

Vibration

0 mm/s

Alarms

0

Health Score

0%

Vibration Measurements (30d)

Alarms (Last 7 Days)

Energy Management & Optimization

Solar %

Power Usage: 32.0 kW

Solar Energy

%

Grid

%

kWh usage

Order & Batch Tracking

| Batch ID | Efficiency (%) | Status |

|---|---|---|

B-2024-001 | 94.2% | Approved |

B-2024-002 | 90.5% | Approved |

B-2024-003 | 96.8% | Approved |

B-2024-004 | 78.9% | Rejected |

B-2024-005 | 82.1% | Review |

Unified Namespace

UNS

ERP

PLM

MES

SCADA

Historian

Cloud

Database

IoT

Point-to-Point

Smart Factory Integrations

Machine 1

Machine 2

PLC

Sensor

UpBlue

Data Processing

Shopfloor System

PO-24-001

Running

PO-24-002

Queued

PO-24-003

Complete

Dashboard

For the manufacturing industry

Bridging the Gap between Shopfloor and Enterprise

OT-IT Integration

UpBlue functions as a no-code protocol converter and creates seamless data streams from operational technology to IT systems. Transform your factory into a uniform, connected ecosystem through our centralized data bus architecture.

- Visual configuration interface

- Real-time data streaming

- Standardized MQTT communication

- ISA-95 compliant structure

UpBlue Platform

One-stop-shop for industrial IoT

From basic integrations to advanced analytics - UpBlue grows with your needs

Proven Results

Customers achieve measurable improvements in their production processes

0%

OEE Improvement

Average increase

0%

Downtime Reduction

Less unplanned downtime

0%

Energy Savings

Consumption optimization

< 0wk

Time to Value

Fast implementation

Frequently Asked Questions

Everything you need to know about implementing UpBlue in your factory